Next Tri-City Amateur Radio Club meeting

7:00pm Monday, Feb 2, 2026

Confluent Makerspace

285 Williams Blvd

Richland, WA

Op Status Of Tri-City Amateur Radio Club Repeaters

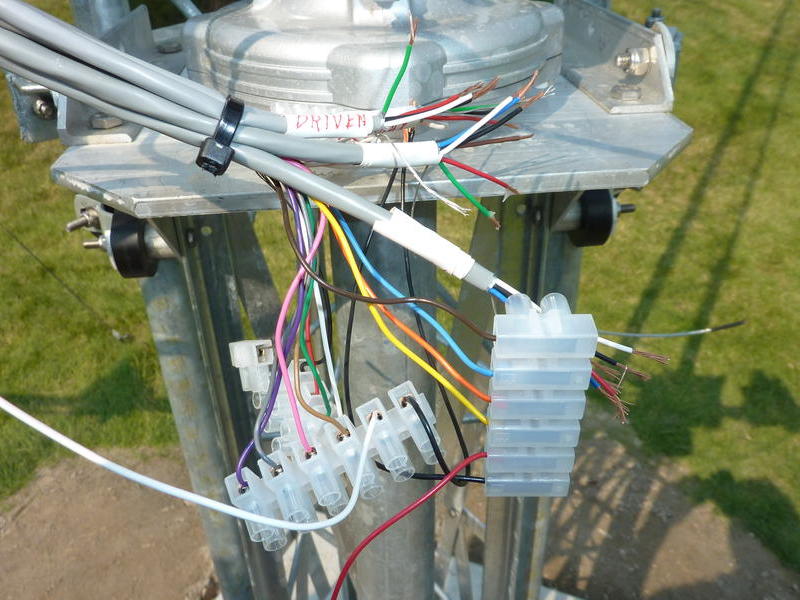

- Johnson Butte 146.04/146.64Mhz: Experiencing Intermittent Noise

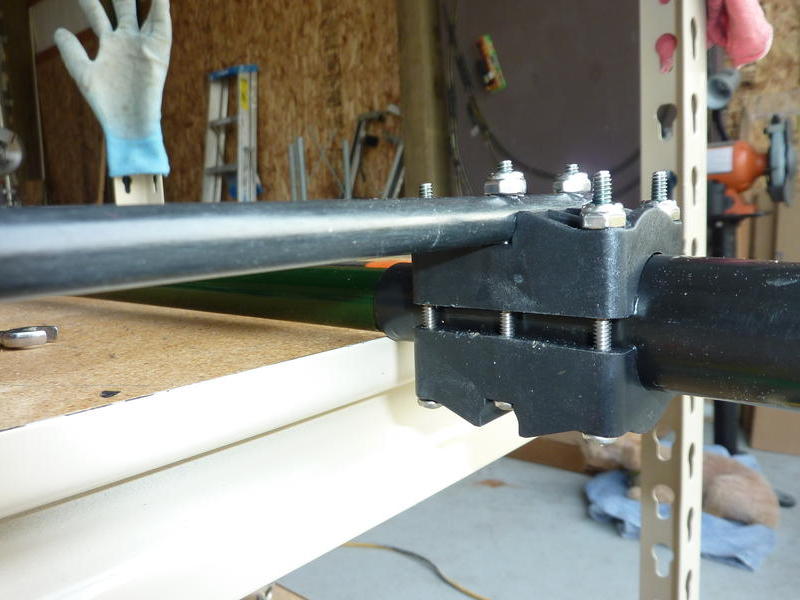

- Rattlesnake Mtn 146.16/146.76Mhz: Down Due To Broken Antenna

- Rattlesnake Mtn 444.1/449.1Mhz: Down Due To Broken Antenna